20mm Oerlikon Cannon

The pictures above show the Oerlikon cannon fitted with shoulder cups and sights, this was usual on British MTB's and seems to also be the case on some of the earlier US PT-Boats (maybe where they were retrofitted to the boats by the crew).

Sometimes there was a bag fitted below the cannon cradle to catch used shell casings and there also seems to have been a strap for the operator.

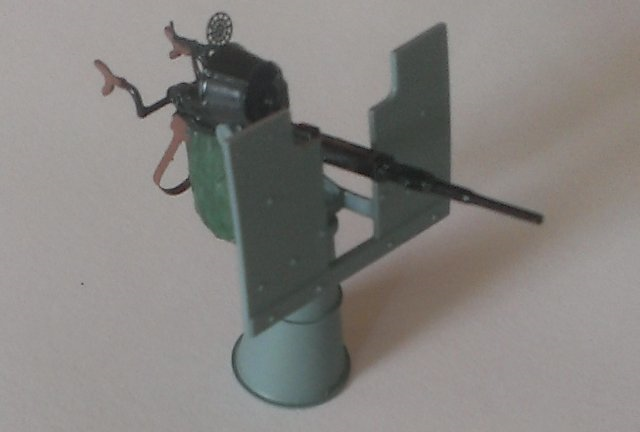

Later US PT's used the leaning brace shown on the model cannon below and they didn't seem to bother with sights. The leaning brace would have given much better control over the guns elevation for shooting at aircraft.

A very good documentary from World of Warships, Naval Weapons, on the 20mm Oerlikon on Youtube: https://www.youtube.com/watch?v=W7qExnBNWJk

Or this one from Forgotten Weapons.com - 4 fun facts about the 20mm Oerlikon Cannon - https://www.youtube.com/watch?v=6yCxITYzW-0

The objective is a (possibly operational) 1/20th scale 20mm Canon.

Excuse the base on the photo above, this is actually the base for the 37mm Canon and if you look at the photo for that canon it shows the correct base for the 20mm.

Basic barrel made from

brass tubing, in order to make the cooling spline I used gold plated wire wrap

pins cut off an IC socket, 16 fit perfectly around the tube, pull eight

forwards, hold them in place with silicon tubing and solder in place, then

remove the other eight, perfect and simple to do!

Basic barrel made from

brass tubing, in order to make the cooling spline I used gold plated wire wrap

pins cut off an IC socket, 16 fit perfectly around the tube, pull eight

forwards, hold them in place with silicon tubing and solder in place, then

remove the other eight, perfect and simple to do!

Another bit of tubing drilled and filed with needle files.

Another bit of tubing drilled and filed with needle files.

Assembly starts

Assembly starts

Leave the silicon tubing on until it's all soldered.

Leave the silicon tubing on until it's all soldered.

Voila!

Voila!

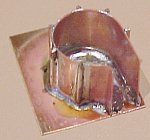

Make some side bits, a bottom thingy and a back bit

Make some side bits, a bottom thingy and a back bit

This shows the sides, bottom, back and a couple of top thingy's in place and the folded leaning brace.

This shows the sides, bottom, back and a couple of top thingy's in place and the folded leaning brace.

Leaning Brace soldered in place

Leaning Brace soldered in place

Looks quite the part so-far

Looks quite the part so-far

The ammunition Magazine folded out of sheet with wires soldered on. Cut around the front and back (not soldered on yet) with scissors and then file to shape.

The ammunition Magazine folded out of sheet with wires soldered on. Cut around the front and back (not soldered on yet) with scissors and then file to shape.

The cradle

The cradle

The cradle and tripod mount.

The cradle and tripod mount.

The tripod legs soldered in place

The tripod legs soldered in place

The base cut out with a hole saw. A countersunk screw in the middle will hold it in place.

The base cut out with a hole saw. A countersunk screw in the middle will hold it in place.

Solder legs to base

Solder legs to base

Brass nut soldered at the top.

Brass nut soldered at the top.

I use the stand drill a lot at low speeds with a range of files to trim up things that are supposed to be round, like the base and the nut.

I am not sure what to do with the finish yet!

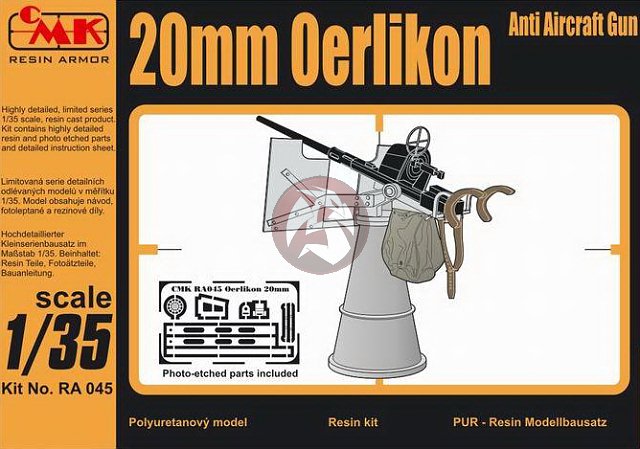

1/35th scale Oerlikon Canon (May 2016)

For the 1/35th scale Elco or the 1/35th scale S Boot I decided to buy a resin kit and make that up:

This is a resin and photo-etch model kit from CMK.

Czech Master Kits, more

commonly known as CMK, has been one of the Czech Republic's contributions to modeling since the mid-1990s.

Originally it focused on production of resin cast kits but later production expanded and a range of

resin detail accessories, detail sets, white metal accessories together with

modelers' tools and aids was introduced. In addition, CMK also publishes

monograph books focusing on interesting subjects which contain detailed scale

drawings as well as original photographs and color profiles.

CMK company is well known to most modelers as producers of very high quality

resin kits and etched brass conversion and detail sets for vehicles and aircraft

in all scales. They have been a very early contributor to the small scale armor

community and known as one of the best companies out there.

This is US version with the USN carriage and front metal shield.

I had a few issues with this kit as the parts are quite small and I'm not, I broke a few myself but a couple of pieces were broken in the box.

I painted this using the recommended colours from the CMK instructions: Humbrol black 33, Humbrol brown 133, Humbrol grey/green 76 and Humbrol grey 87. I have since overpainted the grey with matt 147 grey as this will be on the Schnellboot model.

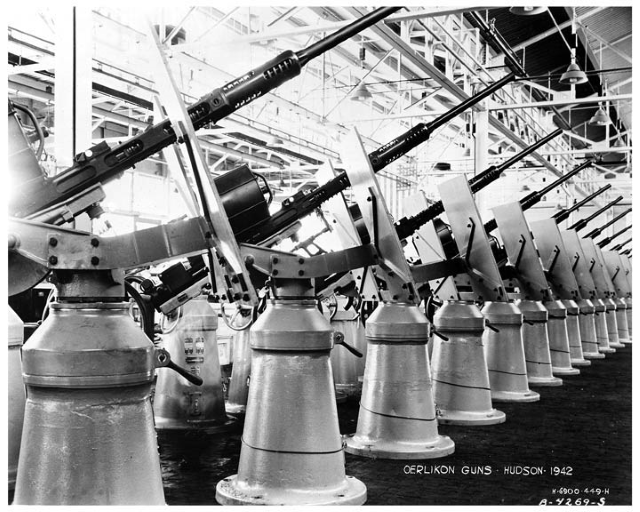

Historical Images

A few Oerlikons circa 1942.