Higgins 78' 20th Scale Hull

This shows the completed Higgins boat with all of it's 3D printed parts and laser cut superstructure. The torpedo tubes are operational and use 100psi compressed air to eject the operational torpedoes.

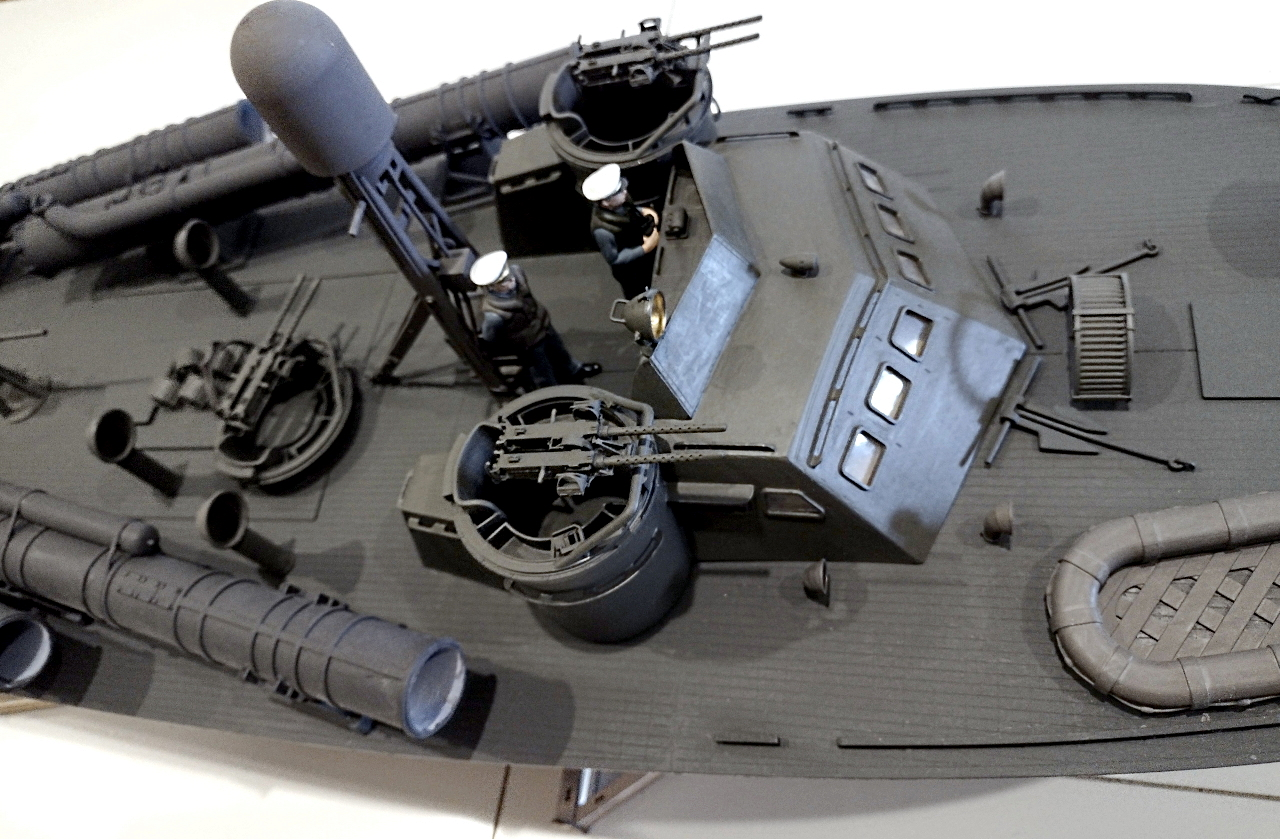

This shows the bridge area in better detail, the 50 cal machine gun turrets, life raft, smaller fwd air vents, anchors, a spare 37mm magazine and a couple of "captain" type crew. I have a set of around 10 crew that I bought from CG trader and 3D printed but I don't want it to be too busy!

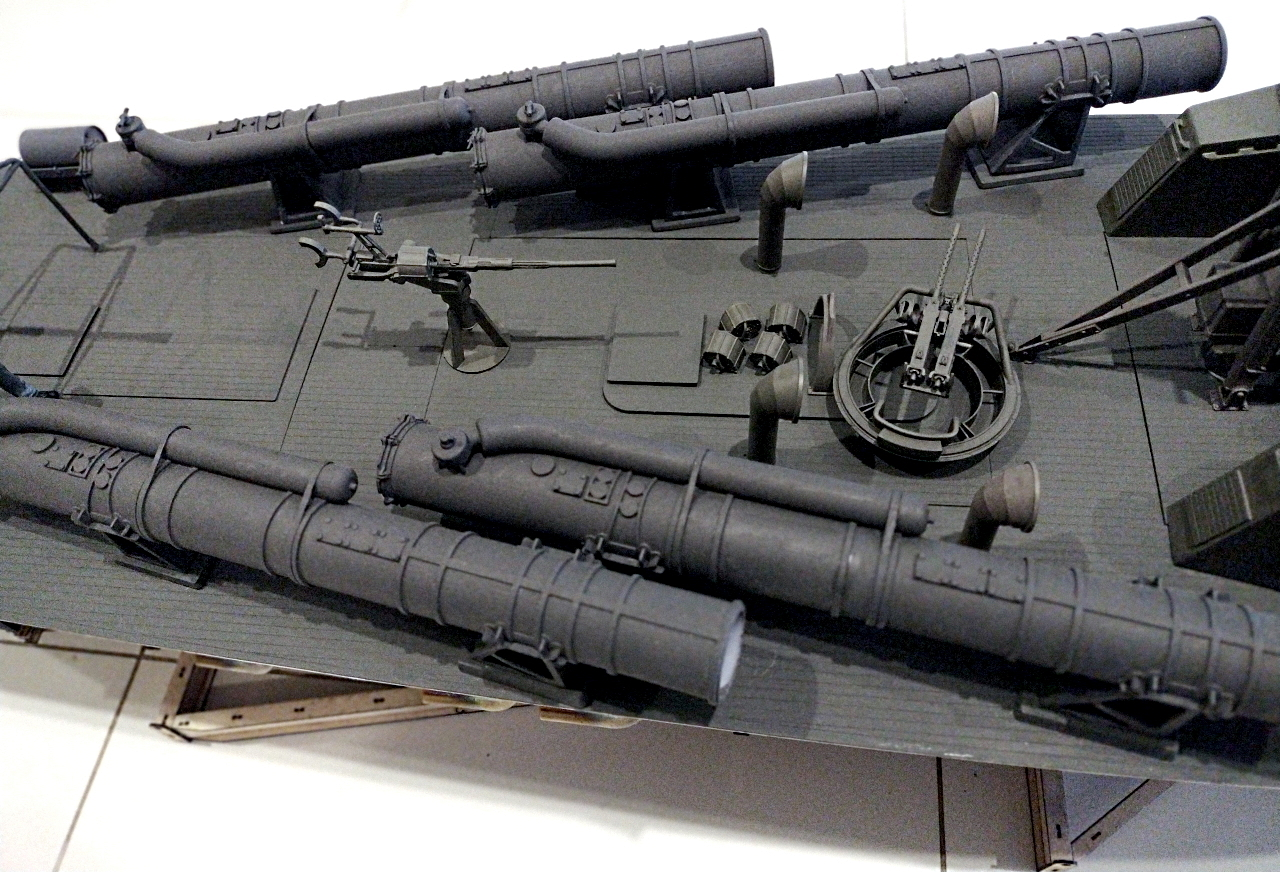

This shows the deck midsection with the Oerlikon 20mm canon, S.O. radar, radar mast support, deck vents and torpedo tube detail. I had a spare 50 cal machine gun setup and some spare Oerlikon magazines so I added them as spares!

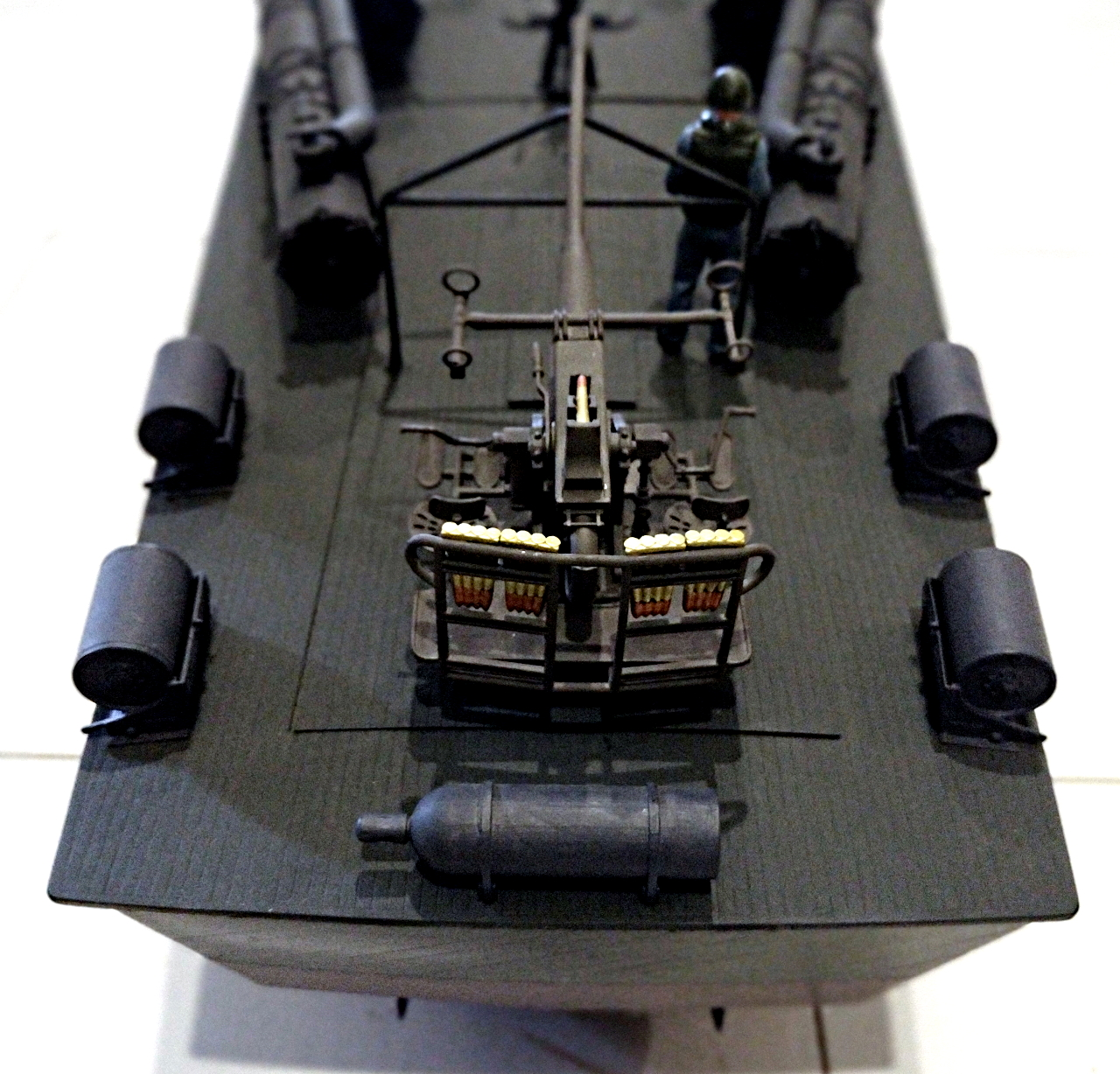

This shows the deck aft section with the 3D printed Bofors 40mm canon, 4 depth charges, the smoke generator, the 3D printed steel depression rail and a crew member. The Bofors sits on a removable hatch that allows access to the steering gear area.

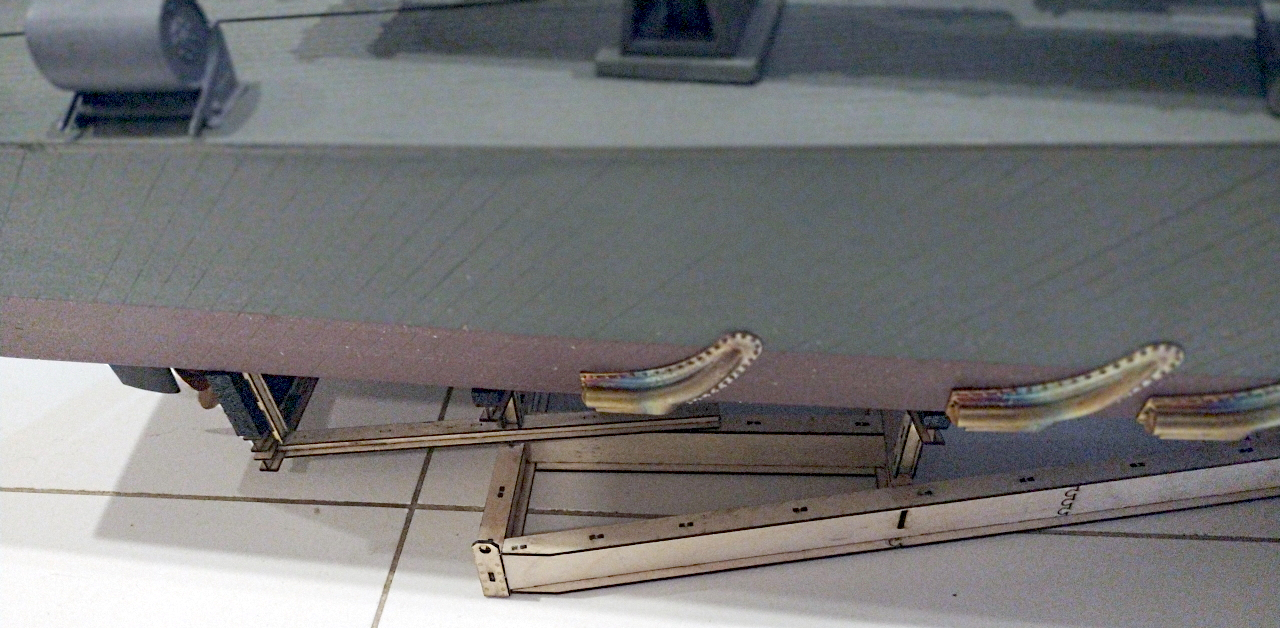

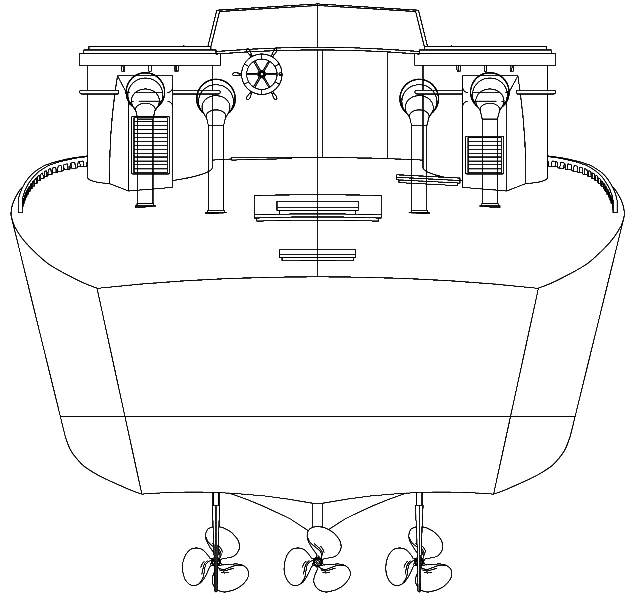

This view shows the exhaust outlets (note: these are hollow bronze 3D printed parts), I heat treated part of each of them on the gas hob to give them a used look, they are not painted. You can also see the laser cut (Elco style) cradle in more detail again unpainted as well as one of the depth charges.

This image gives a good view of the life raft and the 37mm canon, I have the searchlight in solid polished silver in a couple of styles on Shapeways and it has a spiggot in the back of the parabolic reflector to glue a miniature LED onto and a hole to allow the tiny wires to come out through the bottom, so you can make it into an operating search light.

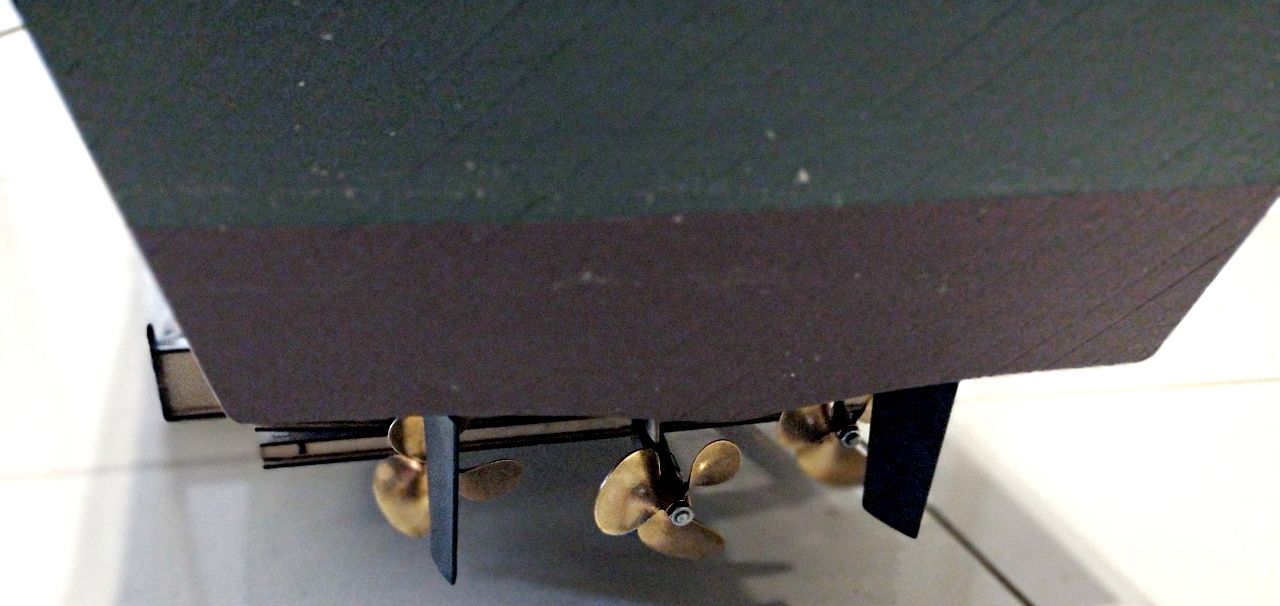

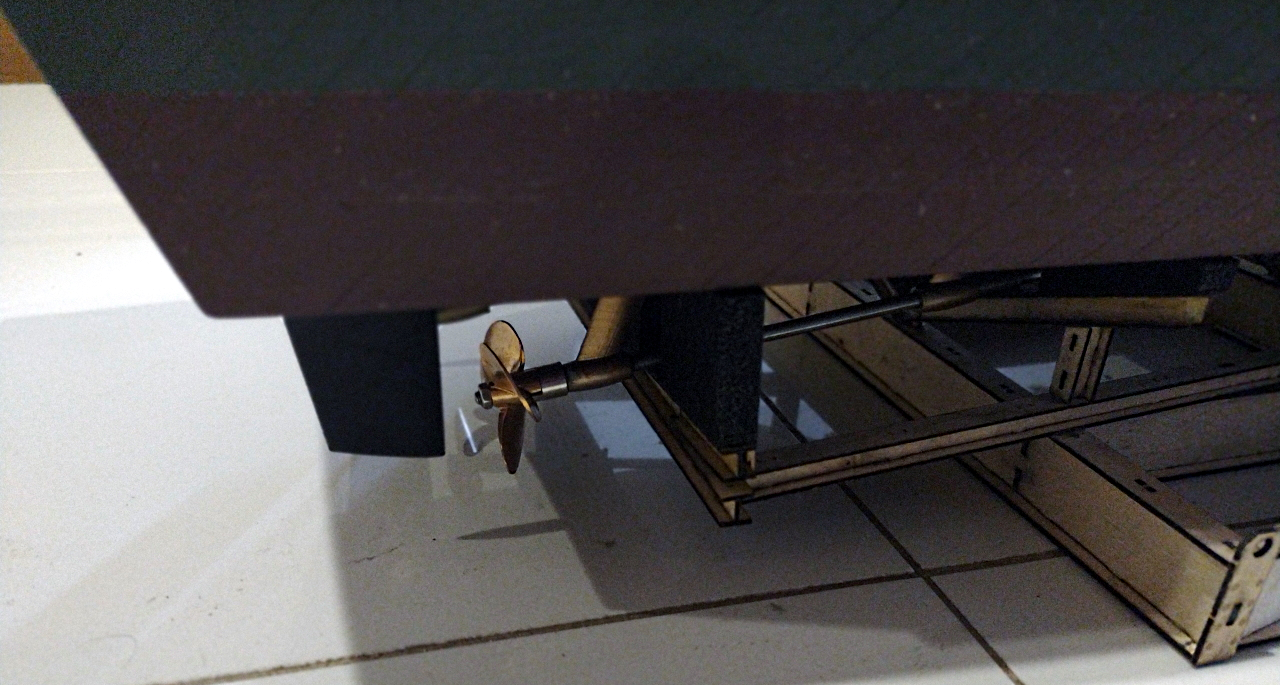

Here you can see my 3D printed bronze propellers, these work really well!

Another view of the equipoise 3D printed propellers, 3D bronze strut, stainless steel 4mm prop shaft and 3D printed rudder. The propellers have a "dog" drive in front and a locking nut at the back.

This video shows the assembly of the Higgins laser cut kit, which I have recreated in a 3D animation.

I have had a few requests for a full Higgins Hull.

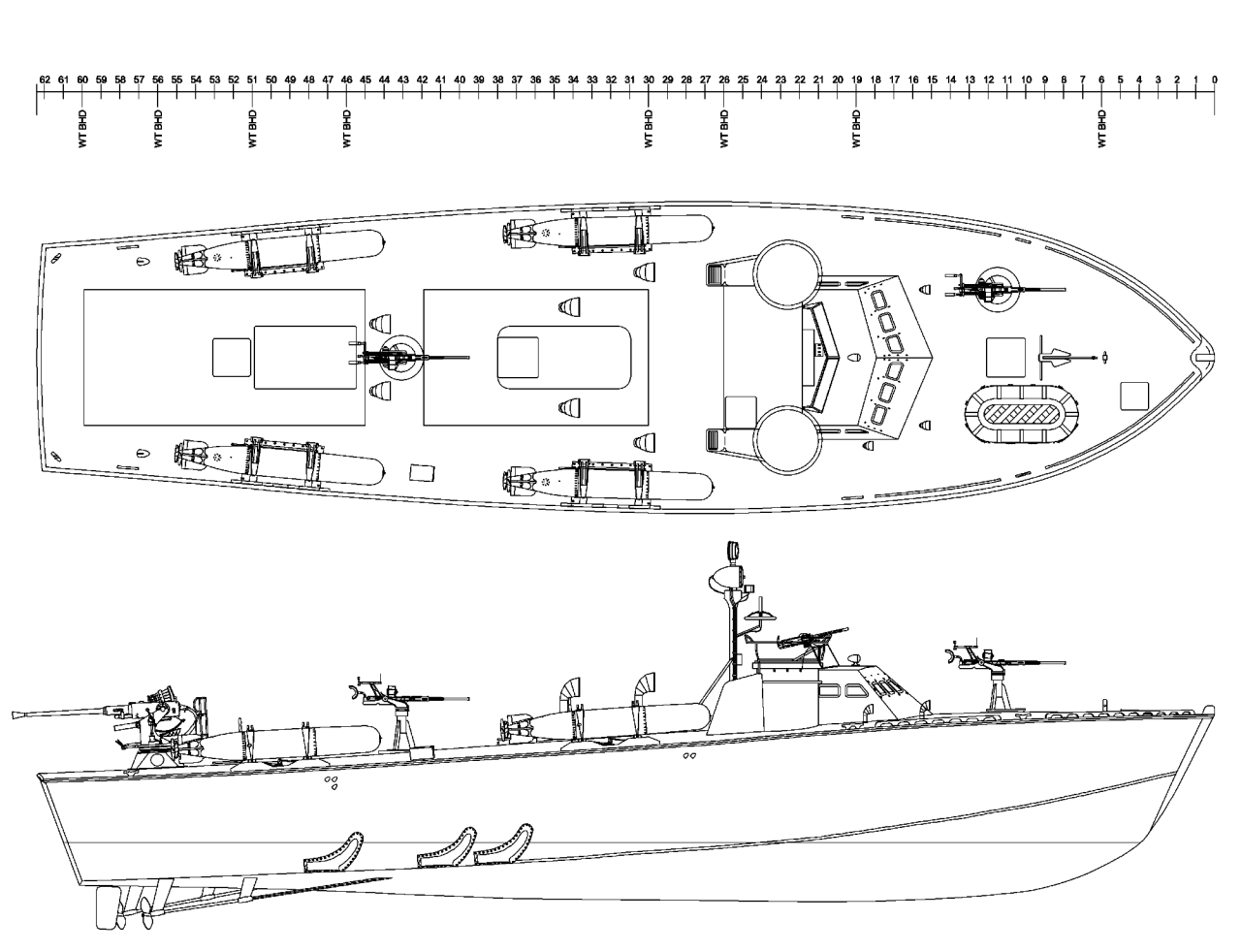

These were built in large numbers during WW2 at the Higgins Industries Plant in New Orleans, Higgins also built many landing craft and other pleasure and military craft and they were very good at building craft that could be beached without damage, making them ideal for landing troops at a beachhead. The Higgins, like the Elco, were bristling with armaments, radar etc. the main difference is that the Higgins 21" torpedo tubes used compressed air to launch the torpedo rather than a small explosive charge, this reduced the visibility of the craft as they produced no smoke, nor could the grease in the torpedo tubes catch fire as sometimes happened to the Elco's torpedo tubes. The Higgins 21" torpedo tubes were fixed in their firing angle and not "trainable" like the Elco and this meant that there was not as much set up time required before a torpedo could be launched.

The Higgins boat hull had extensive plywood bracing internally, a curved transom and much less superstructure than the Elco with no day cabin for the crew. So for the kit I have made provision for large hatches at the deck level, this is not strictly scale but we need to be able to get access to the motors, batteries and stearing gear, I have made all the stations with fixed tops so you can customise it any way you like and make it truly scale if you want to.

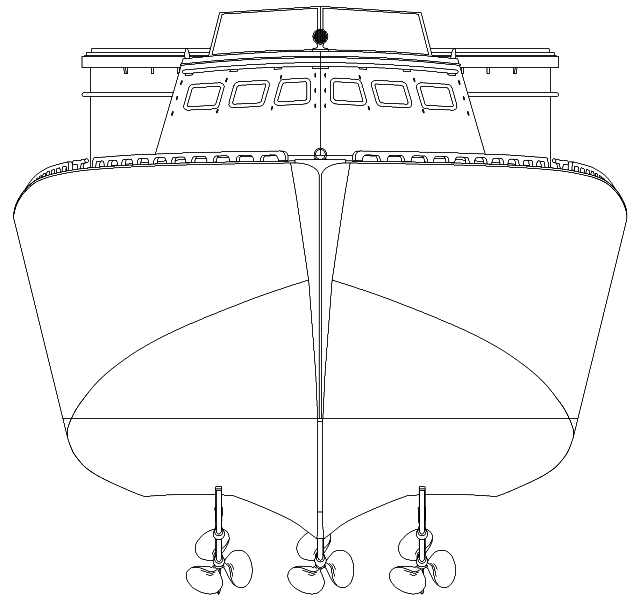

The engines were the same as the Elco - Packard V12 M2500's but were all direct driving the propeller shafts, so no Vee drive gearboxes. The engine exhausts were piped out to both sides to partly submerged mufflers with a closable flap at the rear opening, three on each side, and although the boat had three engines and three propellers it only had two, fairly large rudders, again the propellers were the same 28" Equipoise propellers as the Elco's.

For the Higgins 20th scale Hull I have allowed for three electric motors of up to 42mm diameter, this is larger than the 35mm motors in the Elco 20th scale.

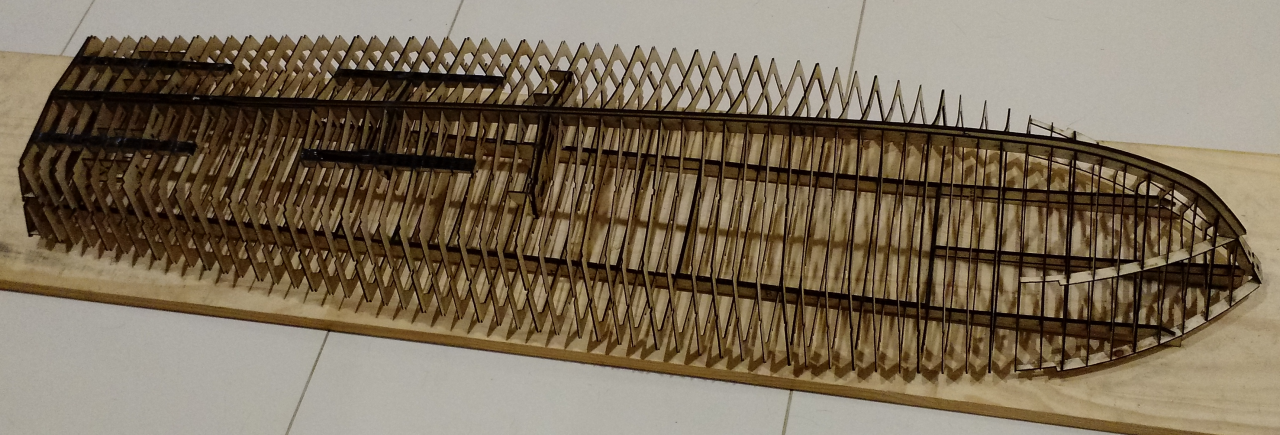

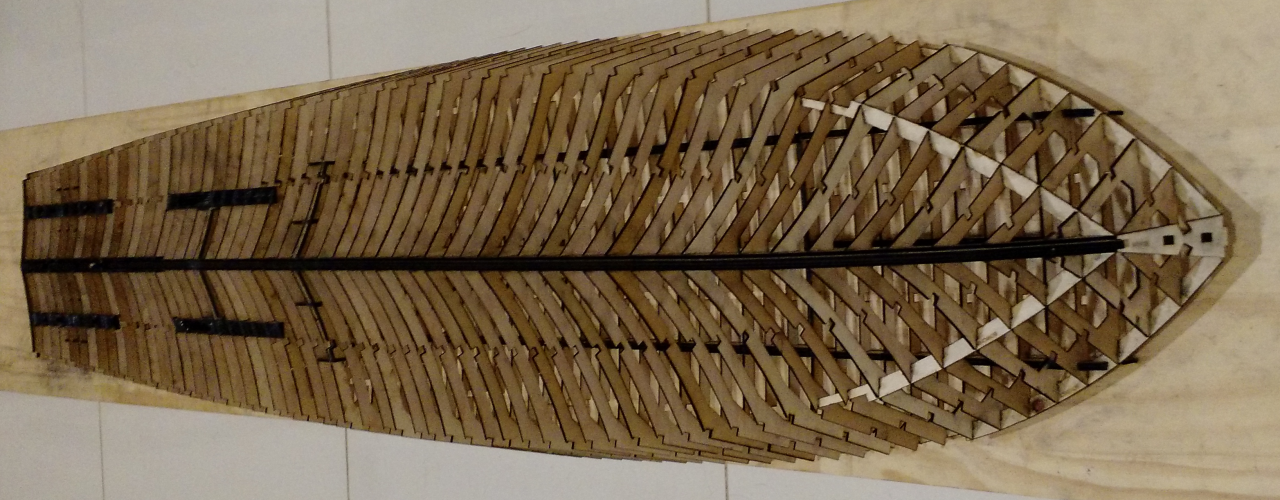

I have recently completed a kit for a very large 1/12th scale (or 1" per foot), so 78" long (or 1981.2mm) this comprises 20 ribs of 3mm plywood plus all the deck runners, keel, servo, rudder and motor mounts and other parts required to make the full hull frame, (except for the long stringer timbers and the covering materials).

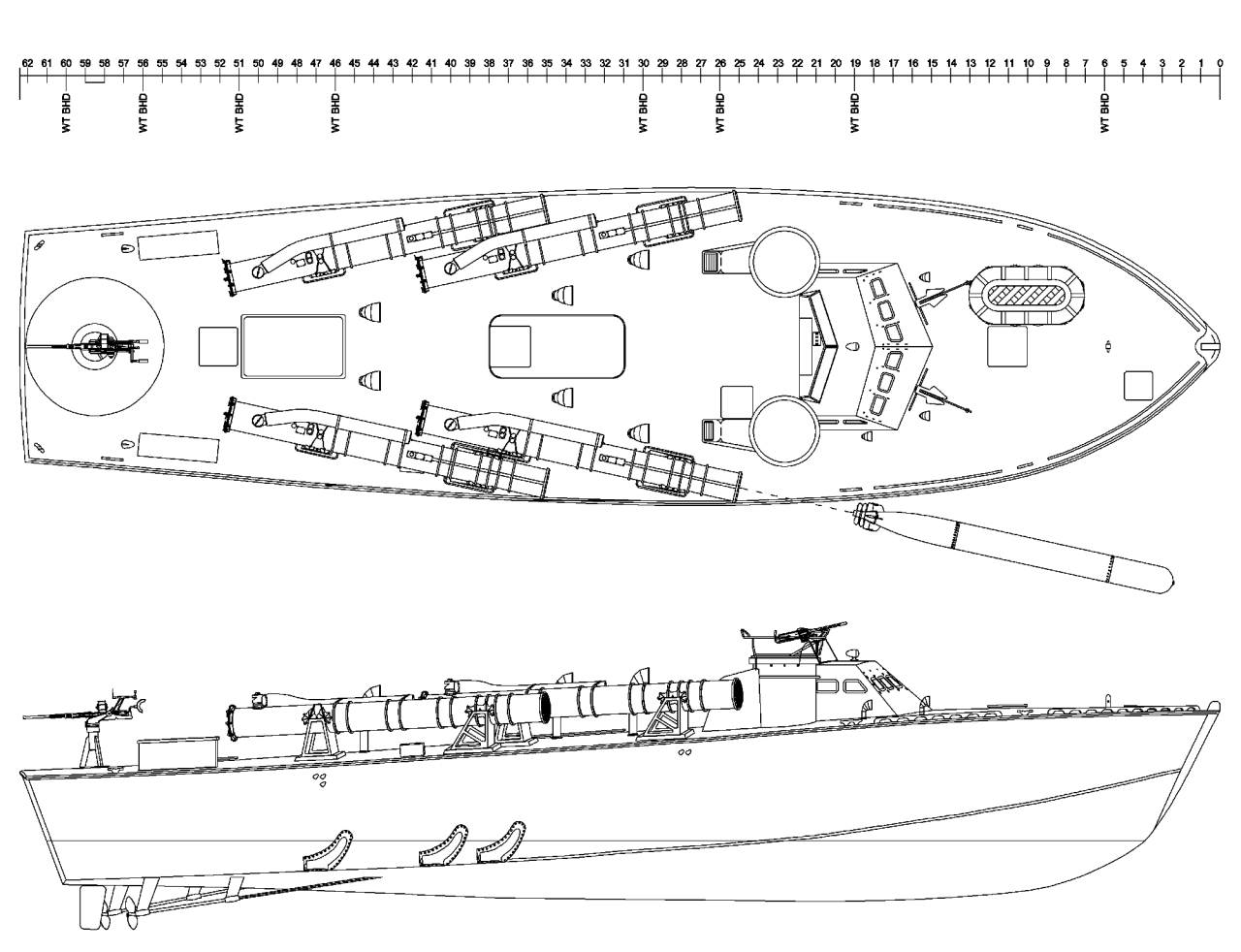

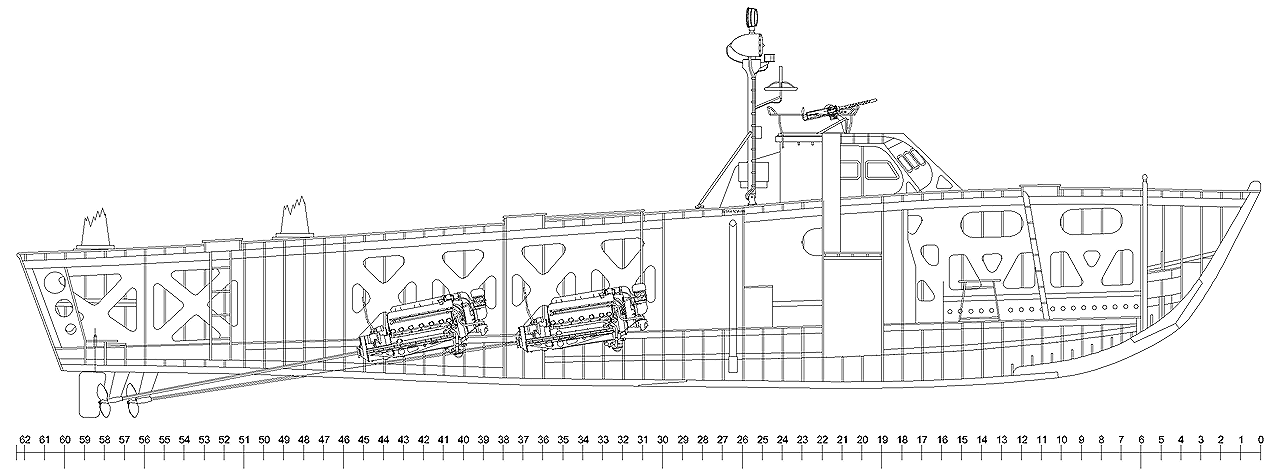

The drawing above shows an early war (PT71) style boat fitted with 21" torpedo tubes.

The starboard side cutaway view.

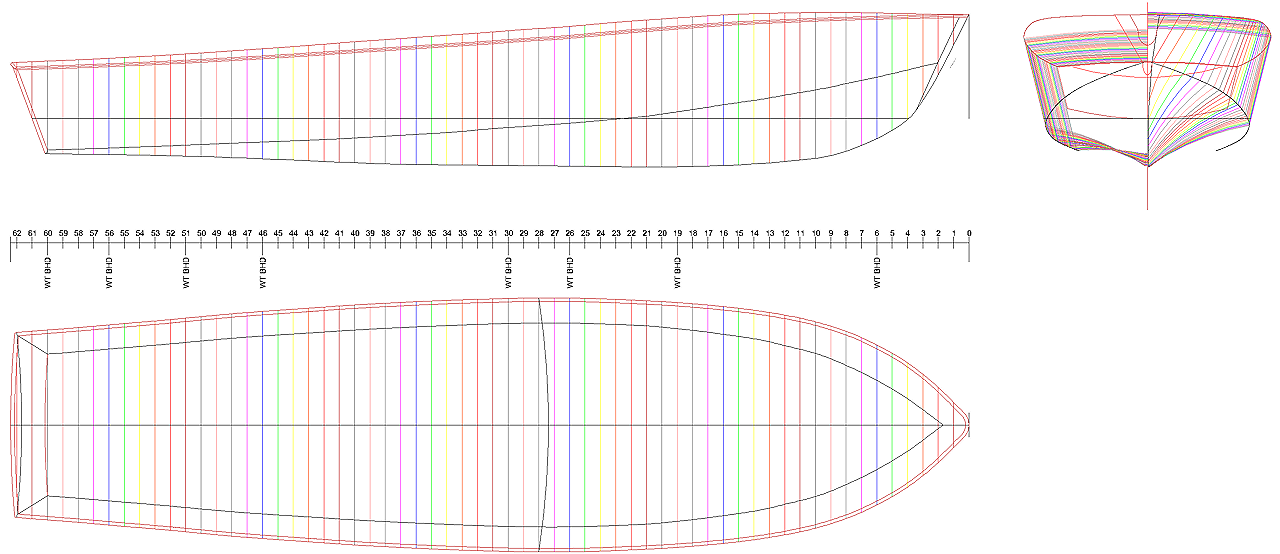

The 78' Hull Lines

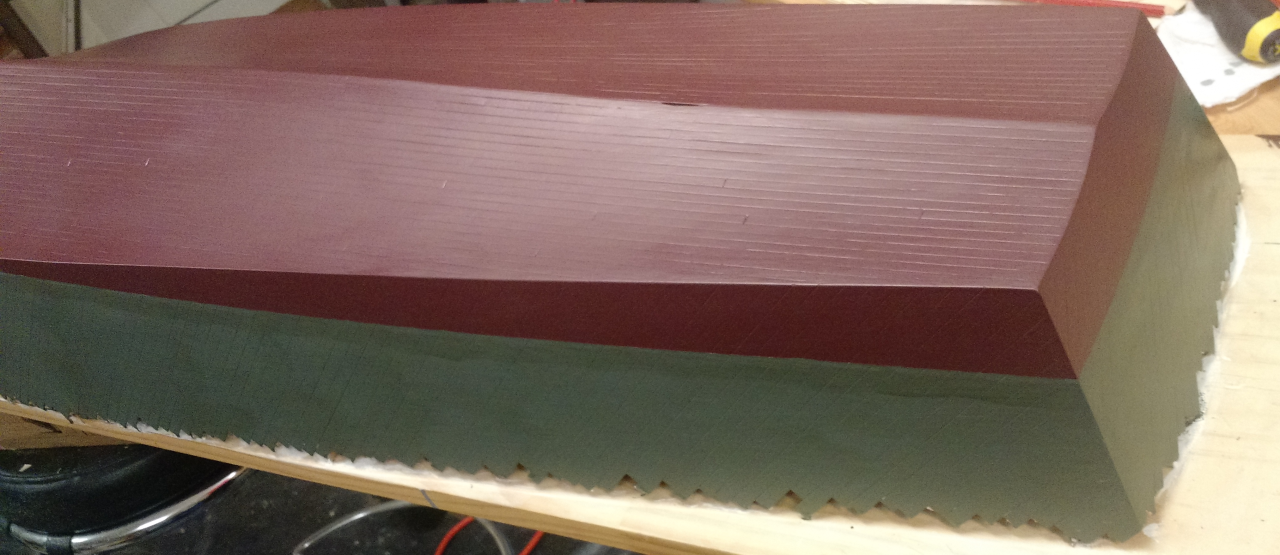

I have produced this hull with all 62 ribs (stations) in the original locations, these were 15" apart in the original boat, every third station in the model kit is in 2mm material and the two intermediate stations are in 1mm, so I will sell the main kit as just 20 ribs with all the keel, deck runners etc.

if you want to you can buy the optional extra 42 ribs separately.

The 20th scale 78' Higgins Hull kit with all 62 ribs (stations) in the original positions (*).

(*) John's note: Except for Rib 1 (station 1) which I have angled and attached to the outside of the keel, once the planking is finished and sanded flush to this rib it will get covered in a "block" of wood and shaped to create the large curved bow sprit that the Higgins boats had.

The transom was curved on the Higgins boat so I have extended the main and rudder keels up the stern to support the transom, this will also get planked over.

(*) John's note: I think making all 62 ribs is maybe going a bit overboard but I think it looks COOL!

The 20 rib kit is on 10 sheets of 2mm Birch ply and the extra ribs are on 16 sheets of 1mm Birch ply.

The above drawing shows a later 78' boat fitted with roll off racks and 22.5" aircraft style Mk13 torpedo's.

This shows the bottom fully planked and the side planking progressing, note I have laser etched screw holes in the scale planking at each rib location, on the sides it is at 45 degrees so there are left and right (port and starboard) planks.

This photo shows Station (rib) 1 which is angled and attached the the front of the keel, once the planking is finished and sanded a laminated nose piece will be glued on and then shaped to get the upper bow curve required.

This shows the planking finished, phew! so much superglue on my fingers, I got sick of filing and sanding it off and discovered after 20 years that PVC pipe cleaning solvent melts superglue and cleans it off brilliantly.

Here is the hull fully painted, a coat of griplock primer and two coats of topcoat. I will cut out and file out the propeller shaft holes before I free it up from the building board.

Finally released from it's construction board and turned up the right way 19/03/2020 (US Date 03/19/2020)

Long deck timbers installed, mostly balsa wood, some spruce, it's not critical.

OK, so the performance of the Higgins was pretty good, around scale speed i'd say? but nowhere near the performance of the Elco, SO I felt it necessary to go buy some more AXI motors from the Czech Republic, the upgraded versions of the motors in the 20th scale Elco (PT593). The existing motors in the above video's were rated at 650KV (Revolutions per Volt) and the new AXI 2820/12 V3's are rated at 990KV, so we should get about a third more revolutions into the props???

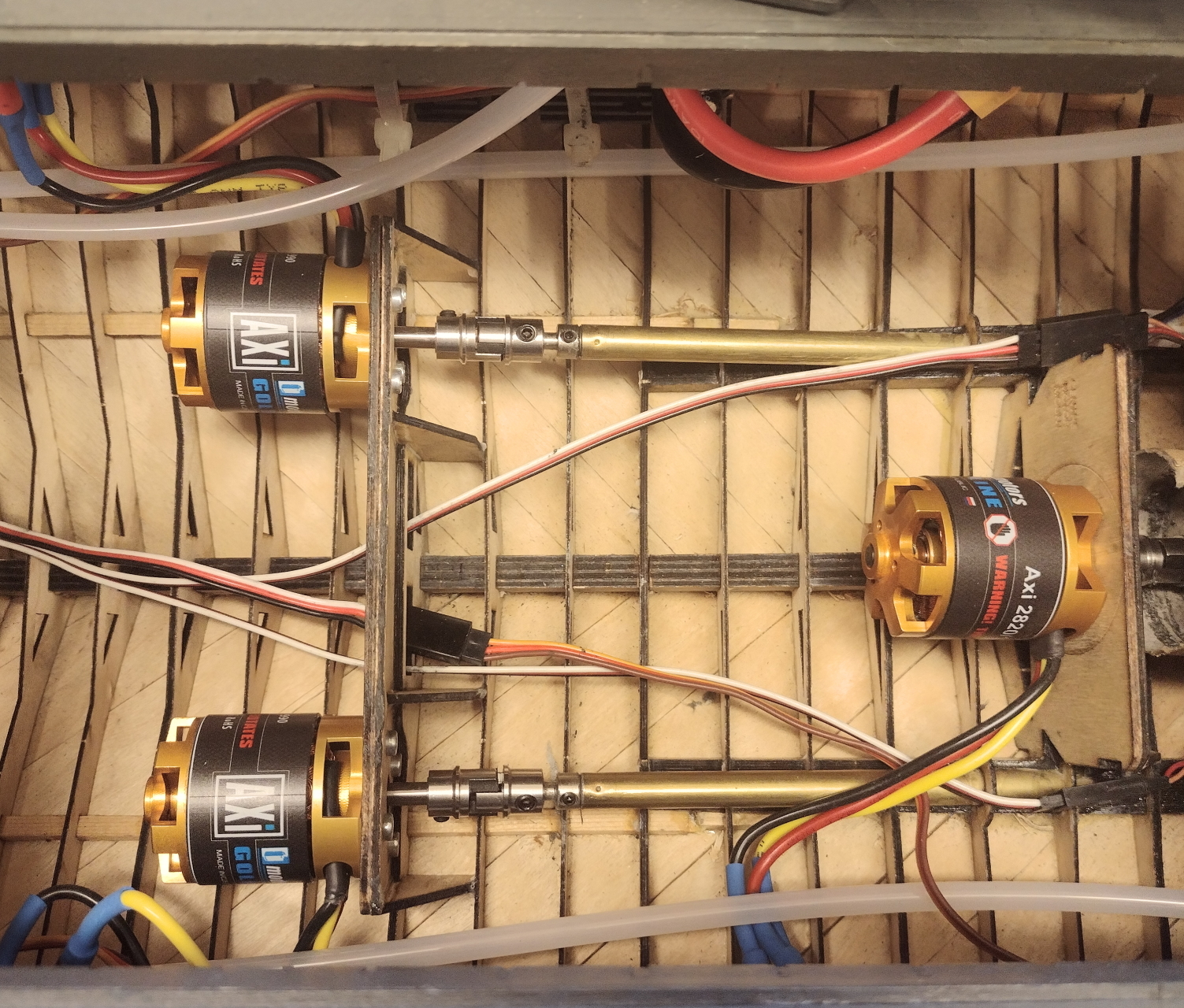

This shows the new AXI motors mounted in the Higgins, ready for the next test drive, These are AXI 2820/12 motors, they are not cheap and they are not as large as the PropDrive's that were in there but they should outperform the existing ones by a huge amount!

I am quite pleased with the universal joints that I have in this boat, they have a rubber block between each half that seemingly reduces the noise transmission through to the hull.

The three "removed" 650KV Propdrive motors are available in the "specials" pricelist, these are in perfect working order and would be great for a slower boat, or if you are just after scale performance.

Note that I have NO water cooling for either the motors or the speed controllers, I have checked the temperatures many times in all of my models and never had a temperature issue!