Epilog Laser Failure

So while I was watching the Epilog laser engraving the last line or so of one of the deck kit sheets it went Pffff and stopped, display went off but the fans were still running, oops I thought or words to that effect!

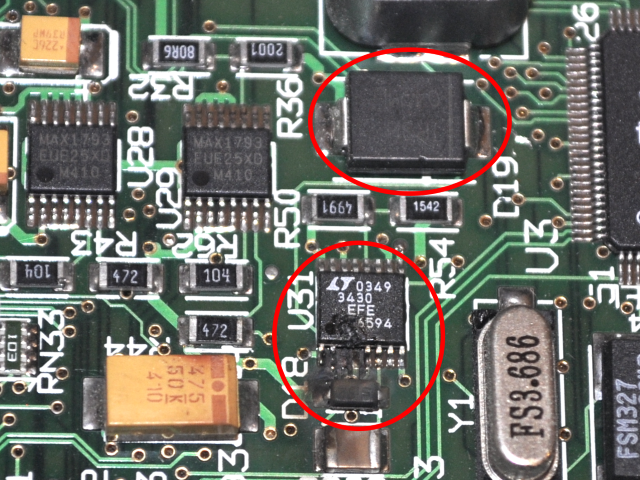

I dismantled the unit and spotted this IC with it's top blown off and no 5Volt power supply anymore, could be serious, emailed the supplier to see if a new board was avaiable, the next day they rang me to see if I would be around for one of their technicians to come and fix it, they are at least an hour away from me so I asked how much, the board itself would be $1500 (Australian Dollars). I'll see if I can fix it myself I said, I don't make enough from the laser to spend that much to get it fixed. I just wanted to know if a board was still available if I can't fix it as the machine is at least 15 years old now.

So I looked up the Linear Technologies LT3430EFE IC which is a high current switch mode power supply. It produces the +5 Volt supply on the main board from the machines main power supply which is 48VDC at 3 Amps, this supply runs the laser tube and the 4 x 12V cooling fans in series, so I downloaded the IC spec and studied it a bit and I checked a few of the support components around the IC and found the large Schottky Rectifier above the IC was shorted both ways and the smaller 914 Diode below it was also open circuit, so ordered some of each and waited for them to come from the UK. Once I removed the IC it was obvious that a track had also blown off the board to pin 3 of the IC, however pin 4 was in parallel with pin 3 and the track to that pin was OK. I cleaned up the board ready for when the components arrived.

Once I received the new parts I soldered them on and repaired the track with a small piece of copper wire and soldered pins 3 and 4 together with it and fed it down the plated through hole next to the pins and next to the 914 diode and soldered it to the plated through hole as well. This track is the main 48V feed from the other side of the board.

From my many years of PCB design experience I'd have to say this track is a little light on Mr Epilog, it should have been a bit fatter and I would have put the IC a bit closer to where the 48VDC comes onto the board as well, I don't think it's a good idea to run 48V all over the board and mixed up with the 5V stuff, just a slip with a multimeter or CRO probe could destroy the board.

My suspicion is that the large schottky diode failed first (shorted) and the main high current switching transistor inside the 3430 IC tried to switch the 48V to a dead short to ground and that caused the bang and blew the top off the IC and vaporised the track. If the IC had failed first I doubt that the board would have survived having 48V all over it.

Anyway all good now and up and running again, cost me about $40 in parts (mostly delivery charges) and a couple of hours to fix. As an aside, I vacuumed the machine out, all those little bits that fall out into the bottom, I also cleaned the work support grid in the dishwasher quite successfully but now the dishwasher smells like burned wood, ah that will wash away!

Reading the IC spec (loads of pages) this little device doesn't like temperature much and can shut down if it gets too hot and can also shut down in a stressful way that degrades the IC over time. I have had a few unexplained issues where the machine has stopped midway through a job and come up with some cryptic X/Y disabled control type error code.

If anybody needs them I have some spares of these components as I needed to buy minimum quantities!

New Air Compressor (November 2017)

For all those people that work from home and annoy the neighbours with an air compressor, I found this little beauty at a new tool store and was so impressed I bought one, all aluminium and very quiet, so now I can laser cut until the wee hours without upsetting anybody, including myself.