Model Torpedoes 2018-2019

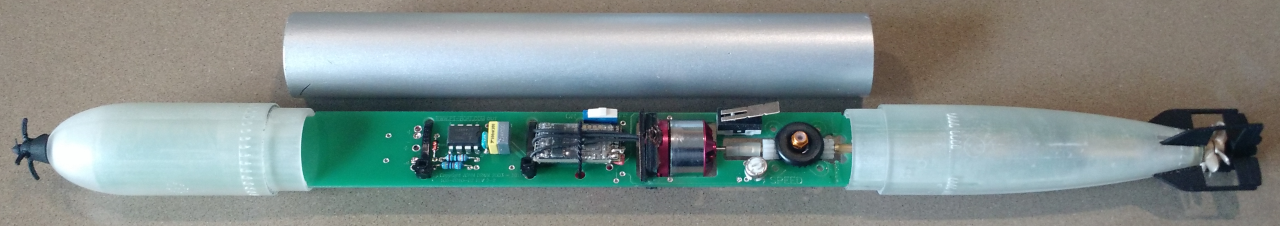

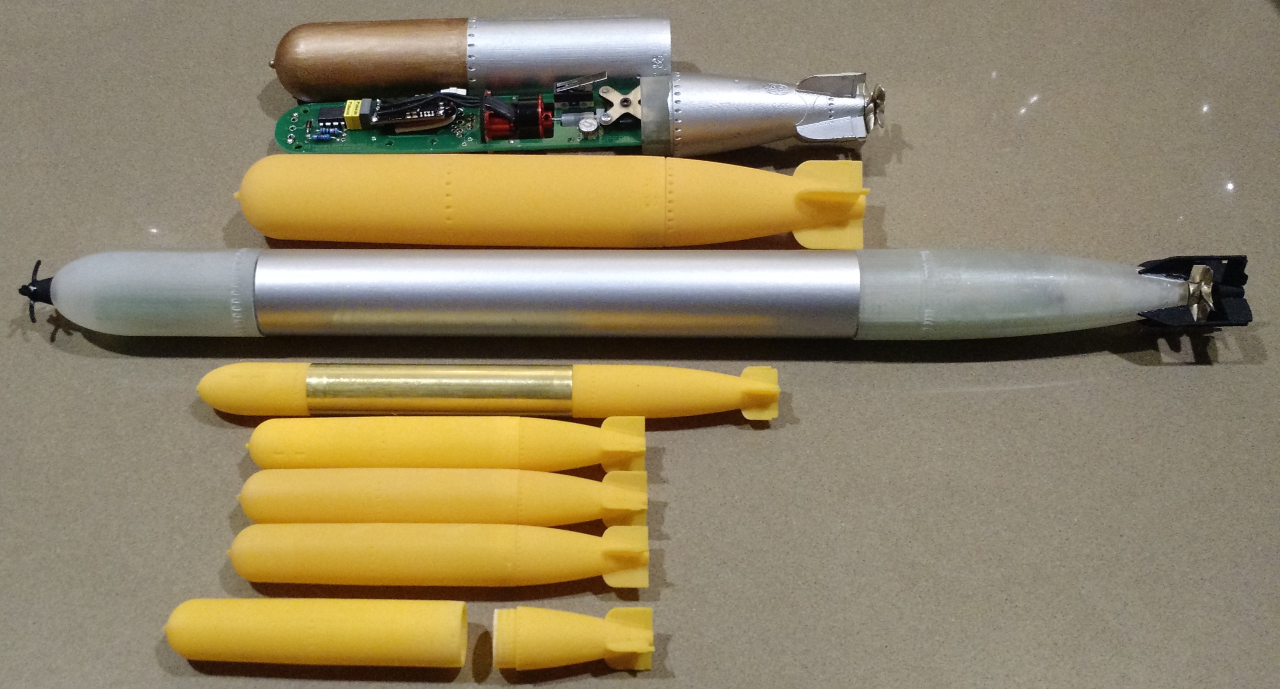

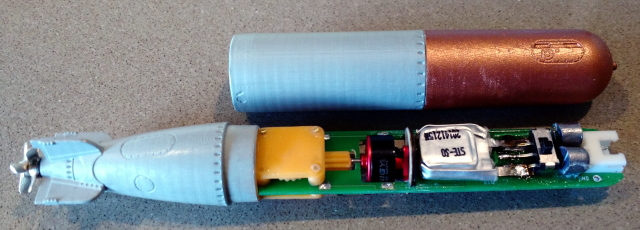

This image shows some production torpedoes, including my new (July 2019) 35th scale US Mk13 printed circuit board with it's 3D printed gearbox and gears and my new 35th scale silver propellers. I am very happy with this little beasty so far and I now wonder why I had so much trouble with the 20th scale version as it has acre's of room by comparison, I still have a few tiny issues to resolve but so far so good, it's operational and also has enough thrust so that it can lift itself out of the water like it's big brother! I had to resort to a third magnetic reed switch in the front, to turn it on, as I could not find any sort of switch tiny enough to fit. I will embed a tiny magnet into the front body so that the ESC (Electronic Speed Controller) and the receiver emulator both turn on when the front body is pushed in place, I have a few magnet contenders on their way including a neodymium magnet that is only 1mm diameter x 1mm long! I must say I didn't expect the 3D printed gears to last as well as they do, no signs of wear so far, and quite a few test runs, I'm very impressed with something that I can just print in the garage! I need a resin that is a little more like nylon or silicon rubber so it grips the motor shaft better though.

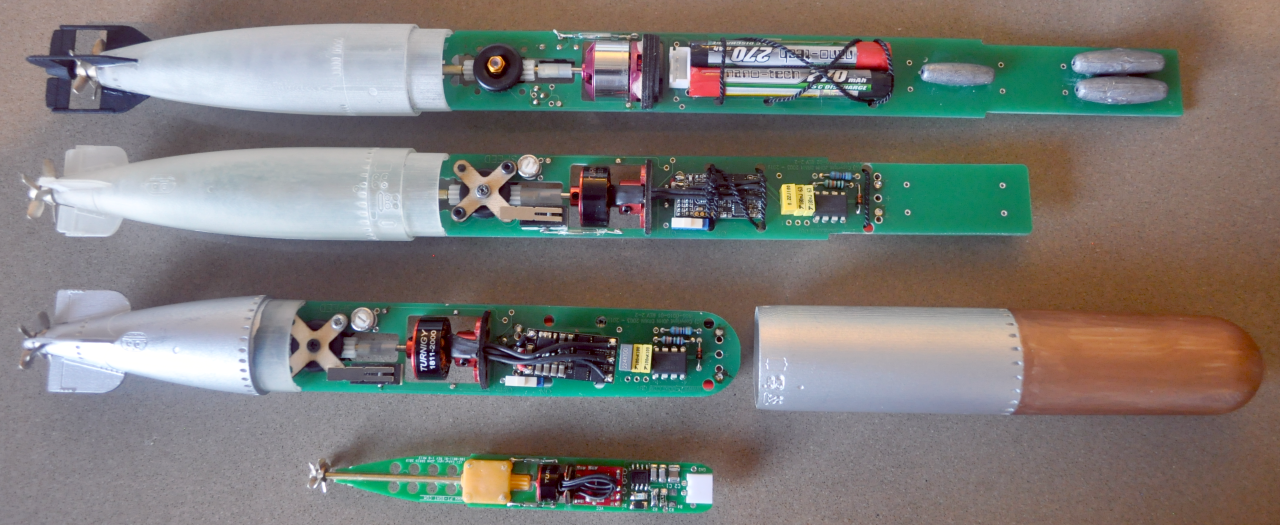

Spured on by the virtual completion of the 20th scale Schnellboot in 2018 I needed to re-invent the model torpedoes that I could never really make for the US Hull-2, these had two major issues, the body could not be reliably made and the motors needed to be modified to have hollow shafts to replace their solid stainless steel shafts. With the advent of 3D printing and the wide availability of small brushless motors and tiny speed controllers both of these issues could be overcome. After much experimentation and somewhat large costs the above represents the basis for a whole family of torpedo versions suitable for both the German and US and even the British models.

The new design uses 3D printed bodies, a receiver emulator operating a tiny brushless speed controller, driving a small brushless motor into a simplified gearbox then turning two counter-rotating propellers at exactly the same speed. The power to drive the torpedo comes from two 270mAH Lithium Polymer (Lipo) 3.7V cells.

The initial G7 torpedo bodies and parts were produced to my design by shapeways in the US, however I now have my own SLA/LCD 3D printer, as the cost of design iterations is a little too high with the shapeways approach and having to wait for 2 to 3 weeks for parts to arrive frustrated me, even though the quality and finish of the shapeways parts was excellent. The font and rear body parts on the torpedo above are all from shapeways. The centre body is made from carbon fibre tubing cut to length and painted.

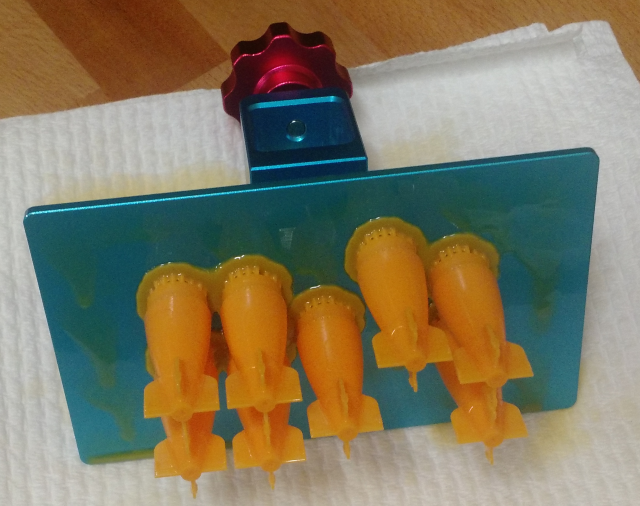

This is the result of my first 3D prints, using my own printer, the top looks good and I was very impressed with the detail and finish but the underside is terrible, due to all the support sprues.

Here is a smattering of different designs, the top Mk13 and the G7 at 20th scale are from shapeways but the rest of the yellow bodies are from my own printer. The one below the G7 is a 35th scale Mk14 with a K&S Brass tube middle body. I am working on the inside for the 35th scale torpedo, using the same design but smaller, I already have silver propellers for the 35th scale and I have produced a better set for the 20th scale.

Mass production of 35th scale Mk13 tails from my printer, these are perfect and I can make 8 at a time!

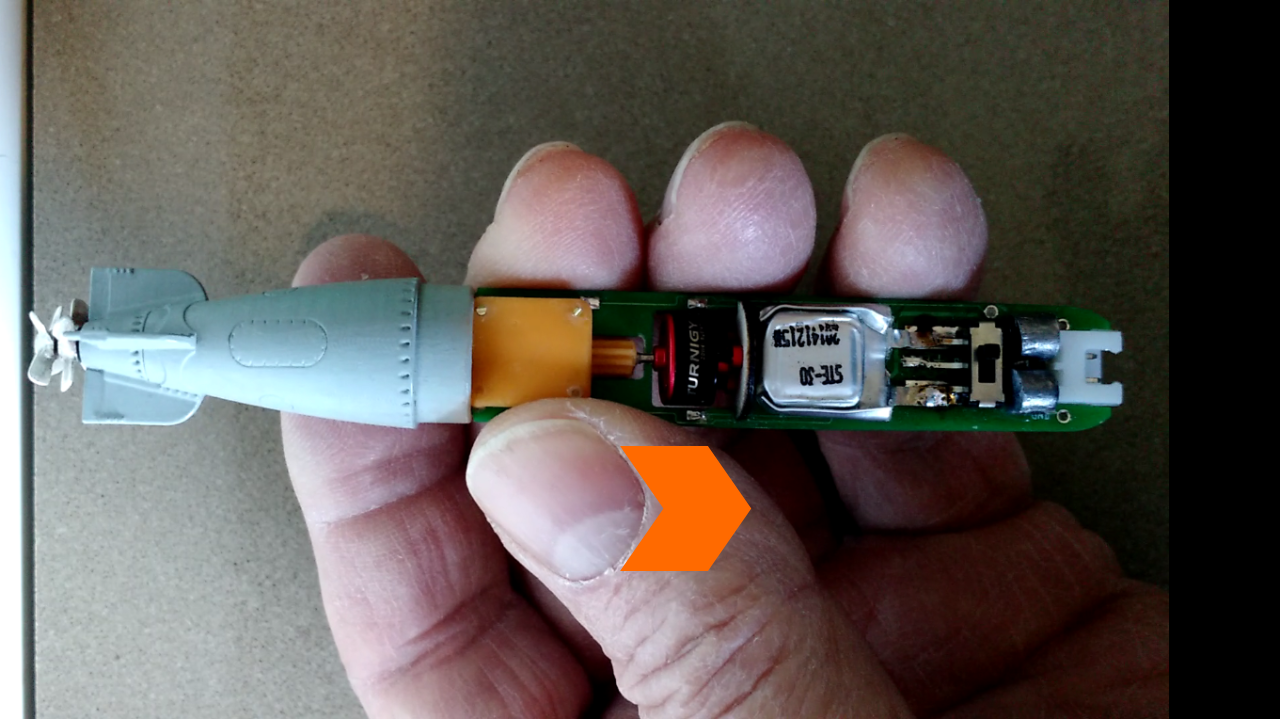

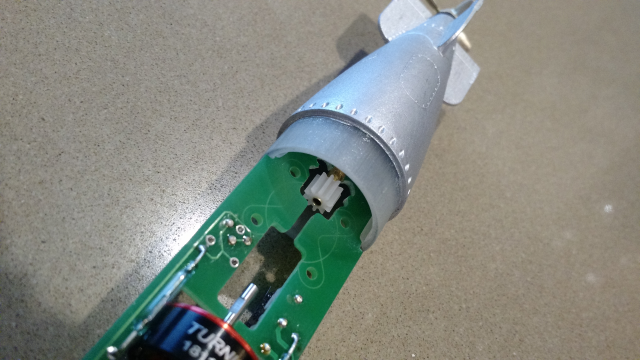

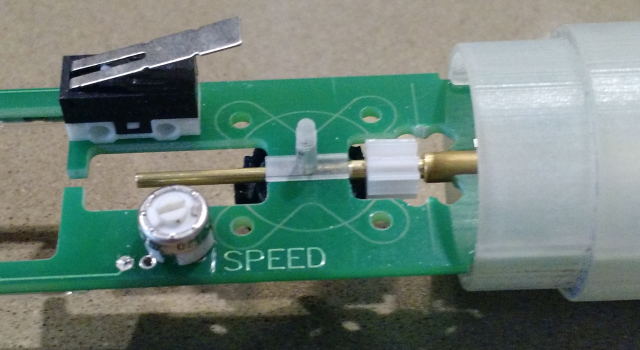

This image shows the rear pinion gear attached to the outer rotating shaft which drives the forward propeller.

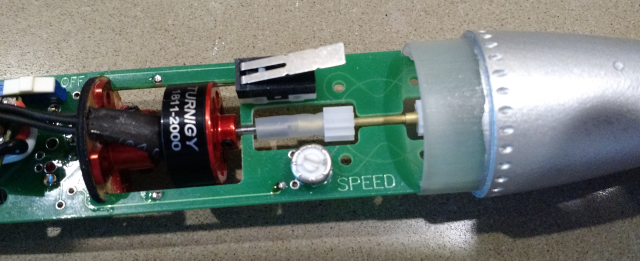

This image shows the forward pinion gear attached to the inner shaft (aft propeller) which is driven by the motor through a flexible coupling. The crown gears connect the two pinion gears and cause them to rotate in opposite directions and at the same speed.

I put the speed adjustment potentiometer where it is, so that I can dip the entire torpedo front, up to the motor, in a waterproofing compound to keep it all dry.

The modified Scalectrix crown gears sit on either side of the printed circuit board and are loosely held in place with the laser cut plywood crossbeams.

This is my later design using a single hollow crosshead assembly to hold the crown gears in place instead of the two laser cut crossbeams and screws. I need to make this out of something more durable though although it is tiny with an M2 thread on each side post so that an M2 nut holds the crown gear in place.

I have been working on the 1/35th scale torpedo inside and I needed some gears for the counter rotational gearbox, I was planning on using the old AFX model car gears but they don't seem to be as available as the larger Scalextric gears that I used in the 1/20th scale so I decided to create and 3D print my own gears and a gearbox body to house them. Trying to fit them in something that is only 14mm diameter is a bit of a challenge though! I initially scaled the Scalectrix gears down from 1/20th to 1/35th but these ended up just too small to be usuable so I increase the size to the largest size I could fit in. I am not entirely sure that the 3D printing resins can produce something rugged enough to last but there is a lot of development going on in resins, so if not now there will be something available in the future. Update - I have ordered some Siraya BLU resin which is supposed to be tough, there is a Siraya TENACIOUS resin which is supposed to be even tougher but I can't buy it in Australia - yet!

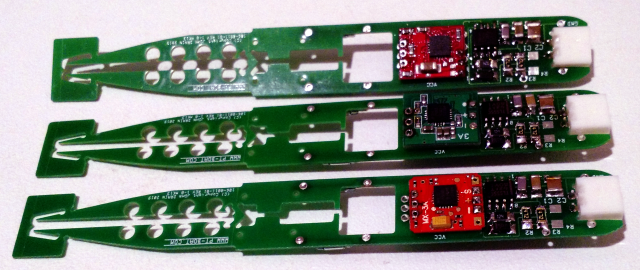

The other issue I have is that the tiny Turnigy 00703 motor that I have doesn't start with the tiny 4A bare board ESC that I have, it just rocked a little and then shut down, so I sent a motor off to the ESC supplier in China to see if they could make it work and they responded with a fix, so one problem out of the way. Update - Turnigy now has a tiny ESC as well so I have bought a few and they work out of the box and they are cheaper, so I have now laid out the 35th scale printed circuit board to suit both types of tiny ESC - The PCB is now being manufactured, only in the US Mk13 version for now though.

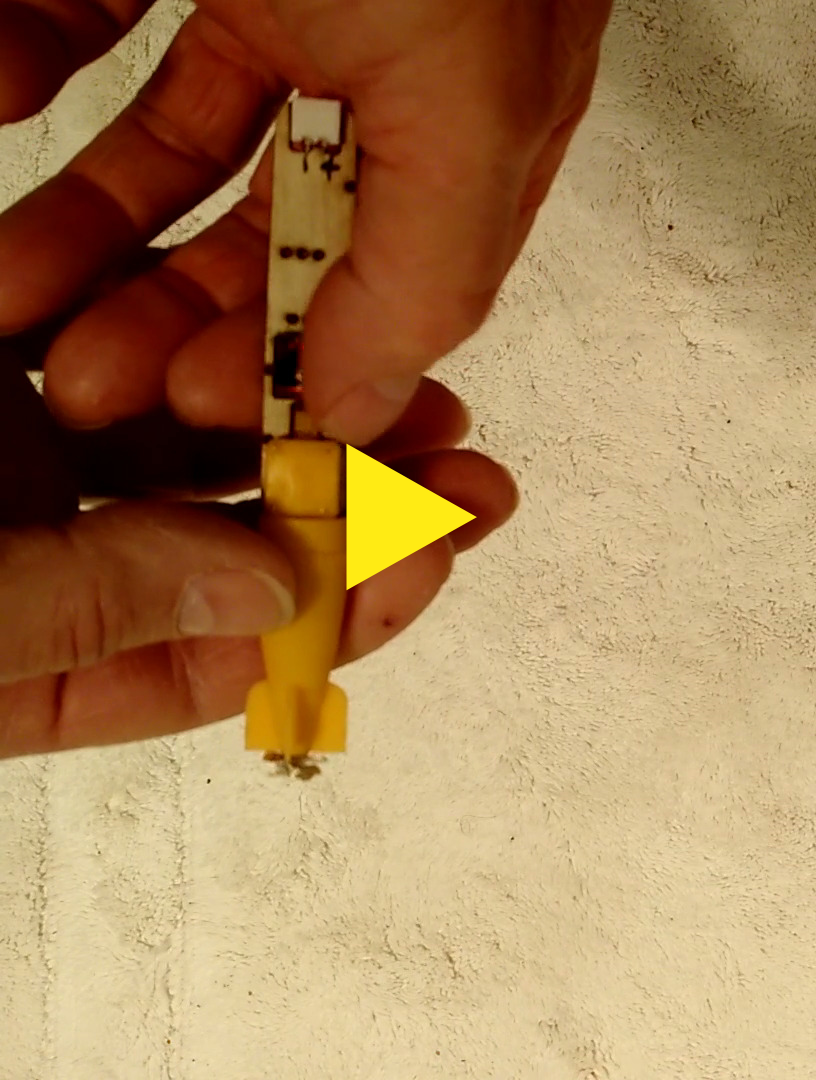

Below is a video of the 35th scale torpedo mechanicals with the 3D printed gearbox in operation.

These three amigo's are completed and working (electronics only) 35th scale torpedo PCB's with three different tiny ESC's, these ESC's are essentially the same designs, all based on the SIL F330 processor and all work perfectly out of the box and all spin the same way by default, the pin out positions are a little different but they all sort of fit the two different footprints that I allowed for on the main board. My idea of a magnetic reed switch to turn these models on failed as the reeds that I first bought were cheap and unreliable Chinese products from a couple of sources and the tiny magnets that I bought were quite powerful Neodymium magnets but increasingly useless the smaller they got. For the two speed control reed switches I have since bought some US made good quality "Littlefuse" versions already formed into a surface mount style, these were nearly $3.00 each but they just work and work and they are also more sensitive than the other rubbish!

The finished 35th scale torpedo complete with weights and the new ultra tiny on/off switch which just happens to fit nicely into the existing board layout and still leaves some room for the front weights. There are a couple of weights in the back section also. The whole 35th torpedo weighs 18 Grams and when it stops it's run it floats with the nose only out of the water. My only need now is for a battery with a little more capacity!

20th and 35th scale Torpedo's will soon be for sale (not painted though, I hate painting).