Cabin Construction

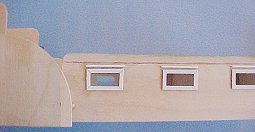

Window frames and gutters are made from 0.1" x 0.040" strip Styrene, 45 degree mitre cut and glued around the timber openings, we will glue some clear material over the inside to make the windows once the painting is finished. (note: the finished Antenna base).

These two parts, the engine room ladder hatch and the ventilator, need to be "finish" painted before they are both glued in place or you will not be able to paint in between them! Likewise between these two and the ammoboxes that sit beside them on the raised deck.

Vent Pipe Boxes sanded prior to painting, 8mm hole for vent pipes (left over brass tube from the prop shafts).

Vent Pipe Boxes sanded prior to painting, 8mm hole for vent pipes (left over brass tube from the prop shafts).

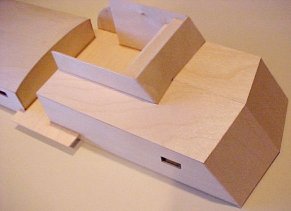

The basic Forward Cabin and Helm

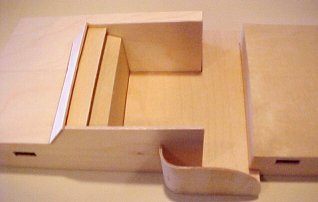

The basic side frame fitted to the curved deck

The curved ply section was made with two layers of 0.8mm (1/32") ply superglued together, prior to gluing they had been soaked for a few minutes in water, bent around in a circle and dried (steamed) in a microwave oven for a few minutes (very quick and very effective but don't use pegs with metal parts to hold the shape or you will get sparks and may damage the microwave oven).

Also please do not overbend the curve when you glue it because it does not spring back, it's extremely strong and you will not bend it back once the glue has dried.

The throttle, lollypop sticks wire and blobs of araldite.

The chart room door

captains headphones - wire and araldite blobs flattened while drying.

captains headphones - wire and araldite blobs flattened while drying.

Is

it worth trying to make these bits?

Is

it worth trying to make these bits?

Underside details

^ I had to cut a section out of this bulkhead to fit the 7AH Battery

The Deadlight frames fit on the front of the forward cabin

The Deadlight frames fit on the front of the forward cabin

The fore and aft machine gun turrets made from 60mm PVC pipe.

Here I've masked off the area where the Ammo boxes go on each side of the rear cabin section deck so that the raised deck section between the engine room hatch and the ammo boxes can be painted before gluing the ammo boxes in place.